Quality Management

AI-Enhanced Cherry Grading with Ellips Technology

Our cherries are evaluated using the advanced Ellips AI grading system, which utilises high-resolution imaging and intelligent software to evaluate each cherry for size, colour, shape, internal and surface quality. A Brix refractometer precisely measures sugar levels, while a Firmtech machine assesses fruit firmness. This integrated technology ensures objective, consistent, and high-quality grading — delivering only the finest cherries to market.

We take great care to grow the best cherries we can, so it is extremely important that they are then handled carefully after picking to ensure they reach their destination – the consumer – in the best possible condition, giving the longest possible shelf life.

To help achieve this, we specifically focus on managing the cool chain process every step of the way.

Wandin Valley Farms was amongst the earliest growers to use the cherry hydro-cooler technology, which was designed to remove field heat quickly and enhance the shelf life of our cherries.

Cherries are then kept in controlled atmosphere cool rooms and transported to the packing facility via refrigerated trucks.

The cool link is continually maintained when the cherries are being packed and once again transported to their destination under refrigeration, with most products packed in modified atmosphere, long life plastic bags.

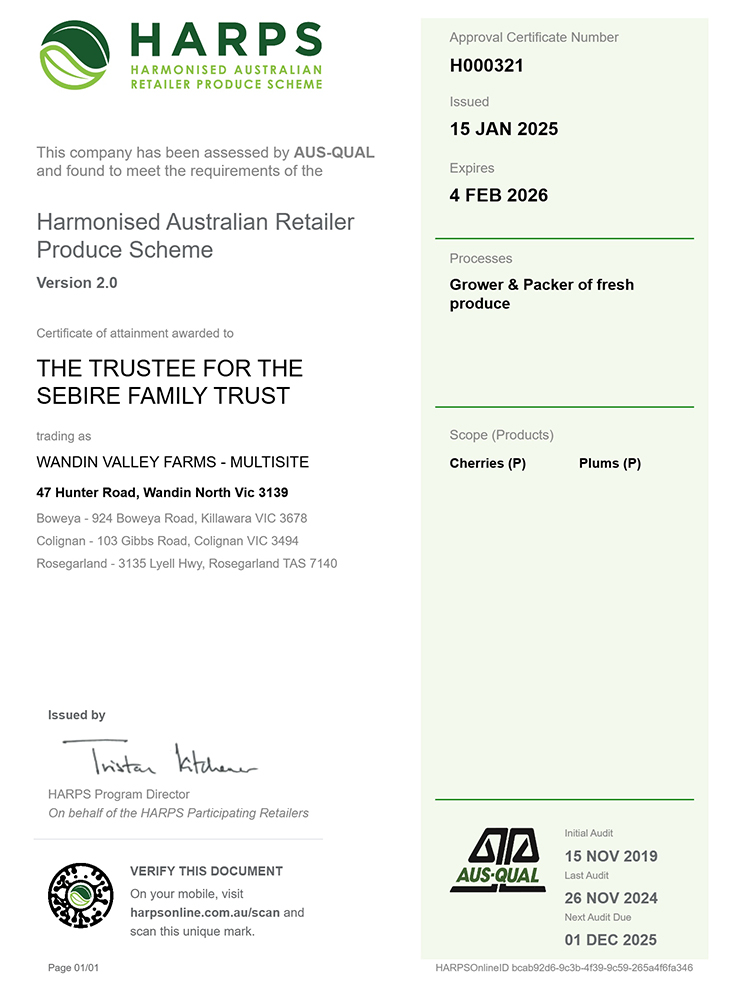

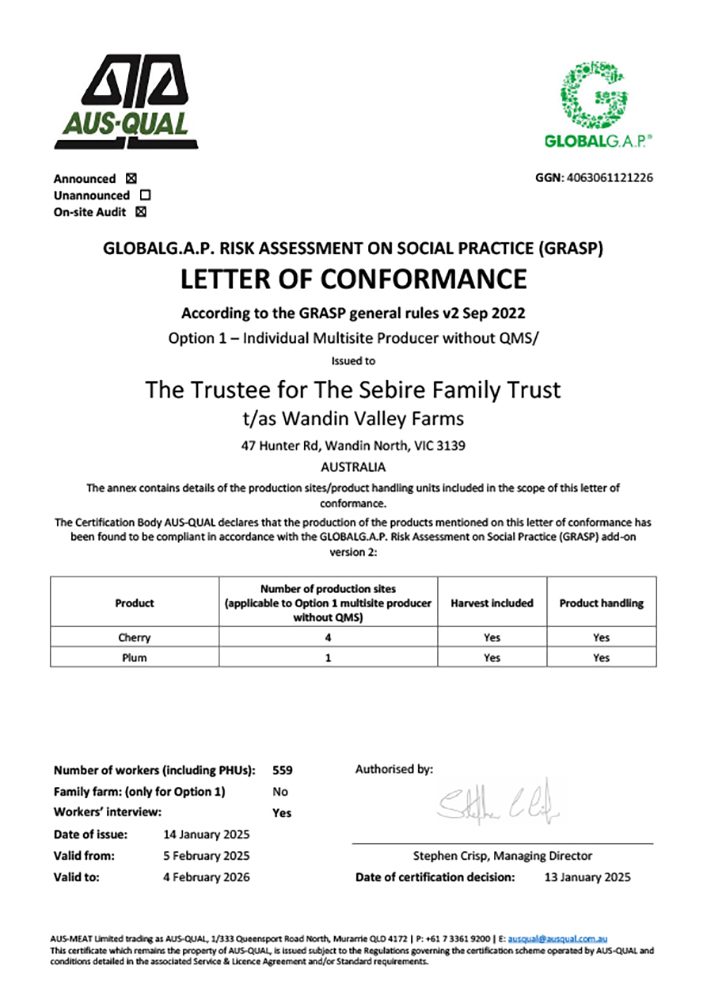

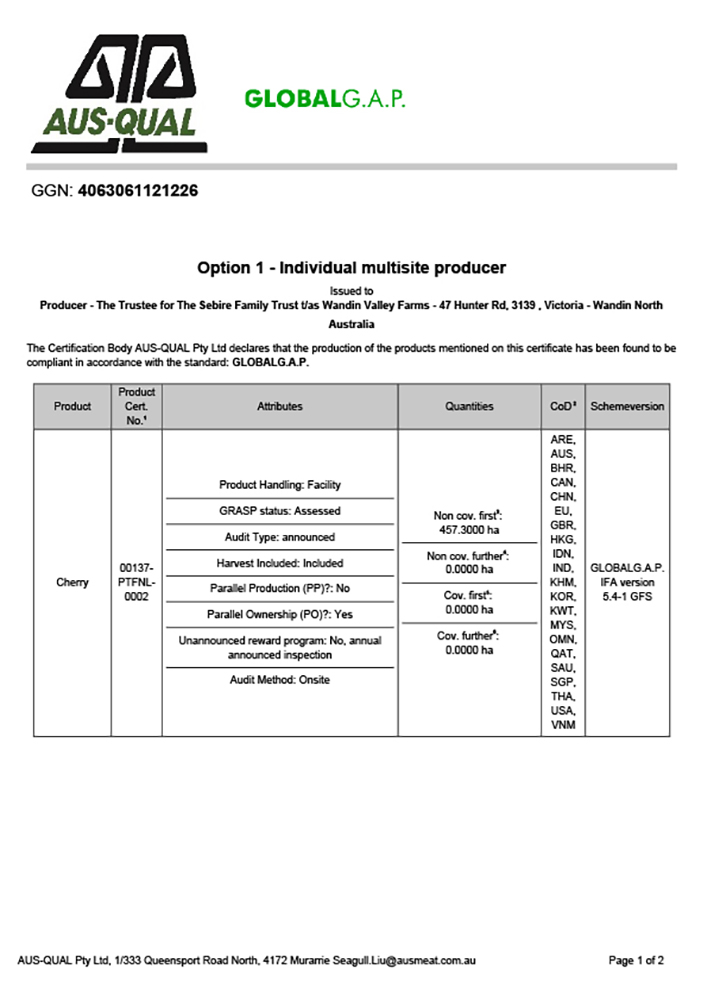

This commitment to the cool chain from orchard to consumer, coupled with HARPS, GLOBAL GAP, FAIR FARMS and GRASPS.

We have certified Food safety and quality systems, which assure the product reaches its destination in peak condition.

Certificates of registration are shown below.